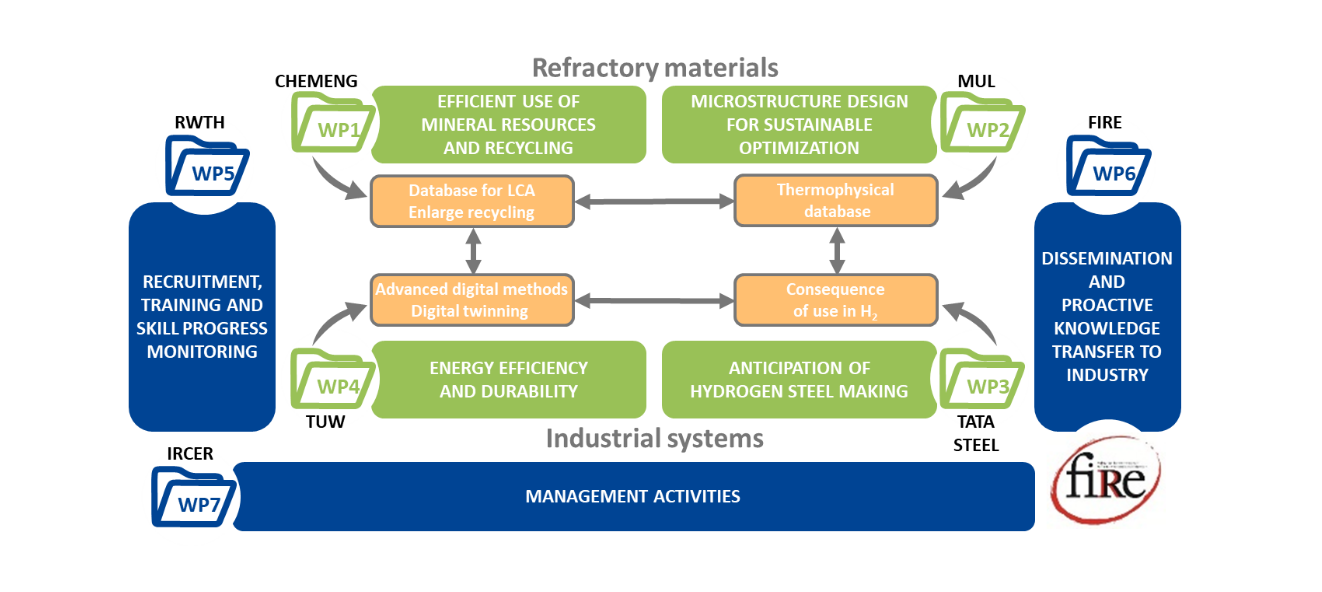

Overall methodology

CESAREF’s objectives are identified through seven individual Work Packages (WPs). The first four WPs will deal with the scientific objectives coupling experimental, numerical, and environmental aspects like in similar networks of public and private actors. The last three WPs are dedicated to the training and outreach activities, coordination of the network, and dissemination of results.

WP 1 - Efficient use of mineral resources and recycling

Efficient use of mineral resources and recycling will deal with the 4 challenges associated with circular economy: feed the loop, design the loop, slow down the loop and close the loop. The Life Cycle Assessment methodology (LCA), which has become a standard environmental evaluation tool (ISO 14040 – 14044:2006), will play a key role in this WP. Feeding the loop in a sustainable way requires knowledge about raw materials extraction (including secondary raw materials) to build robust inventory databases. Designing the loop means having access to relevant production routes of several types of refractories (bricks, precast blocks, unshaped products), to optimize them in an eco-design perspective. Slowing down the loop refers to the value of the environmental footprint of the refractories once applied in the steel industry. The impact of several operating parameters has to be assessed to both reduce the environmental impact and costs associated to refractories for the steel industry. Closing the loop means working on recycling routes and the associated environmental impacts, including the recycling process and re-use of secondary materials, relying namely on model material systems. WP1 will benefit from the CESAREF industrial network, to access the required primary resources allowing relevant inventory databases to be built, calculate the environmental impacts (climate change and resource depletion among many others), and propose eco-design strategies so the sector contributes to the EU Green objectives.

PhD positions focusing on this work package: PhD 01, PhD 02, PhD 03

Involved PhD positions: PhD 04, PhD 05, PhD 06, PhD 07, PhD 08, PhD 09, PhD 10

WP 2 - Microstructure design for increased sustainability

Microstructure design for increased sustainability will deal with the characterization of selected materials at room and high temperature in virgin state, after service, or after exposure to H2 or other combustion atmospheres. Conventional and specific experimental techniques, based on the use of European large-scale facilities like synchrotron radiation sources, will be used to determine the relationships between structure, microstructure and macroscopic properties. Alongside thermal expansion, thermal conductivity will be tested, as well as the Young’s modulus by ultrasonic echography or the resonant frequency method. X-ray tomography and diffraction under synchrotron radiation source will be applied to investigate structural and microstructural evolutions of refractories in service or due to H2 containing atmospheres. Stress-strain relationships and creep laws will be determined from tension and compression tests and work of fracture by wedge splitting tests. WP2 will take advantage of the CESAREF network to apply complementary experimental devices useful for each task. If different methods are available within the network, the most appropriate will be used to obtained key experimental results and improve the global outputs of the project.

PhD positions focusing on this work package: PhD 04, PhD 05, PhD 06, PhD 07, PhD 08, PhD 09, PhD 10

Involved PhD positions: PhD 03, PhD 11, PhD 12, PhD 13

WP 3 - Anticipation of Hydrogen Steel Making

Anticipation of Hydrogen Steel Making will deal with the acquisition of science-based knowledge on the long-term behaviour of refractory materials in the new emission-free processes. The conversion to emission free industrial processes as requested by the European Green Deal will lead to the replacement of carbon-based by hydrogen-based fuels. Several options for hydrogen-based ironmaking are presently being tested on a pilot scale level. The most promising breakthrough technologies need to be tested and implemented on an industrial scale between 2020 and 2030 and beyond. The time pressure to ensure the process changes, and consequently change enabling process parameters such as refractories, is enormous and research is needed. The application of refractories has to be revised due to drastically changed process conditions in both iron- and steelmaking, and in more downstream processes. Extensive characterization of the relevant refractories materials (WP2) is urgently needed, and the results thereof will form the backbone of this work package.

PhD positions focusing on this work package: PhD 11, PhD 12

Involved PhD positions: PhD 04, PhD 09, PhD 10, PhD 15

WP 4 - Energy efficiency and durability

Energy efficiency and durability will deal with leveraging advanced digital methods to reduce heat losses in the steel making process and prolong the useful lifetime of refractory linings and components. The basis for the novel methods to be developed in WP4, is accurate real-time data on the thermal state of steel ladles and the condition of the refractory lining. To collect the required data new monitoring methods aided by machine learning and data driven approaches will be developed. Experimental data will be augmented with data from detailed simulation models. The insights gained from these monitoring and modelling methods will be transferred to the steelmaking process to support the decision making regarding reduce/reuse/recycle/recreate and employing the steel ladles. To incorporate the process perspective in the decision support, an optimization model for the ladle logistics is set up, which not only takes the thermal state and the remaining useful lifetime of the refractory lining into account, but also considers the limitations of the steel making process. Incorporating this new information in the decision-making process will result in a reduction of resource consumption (gas, refractories, hot metal) and greenhouse gas emissions, thus directly contributing to the objectives of the European Green Deal. For validation, dedicated experiments in a steelmaking plant will be conducted.

PhD positions focusing on this work package: PhD 13, PhD14, PhD 15

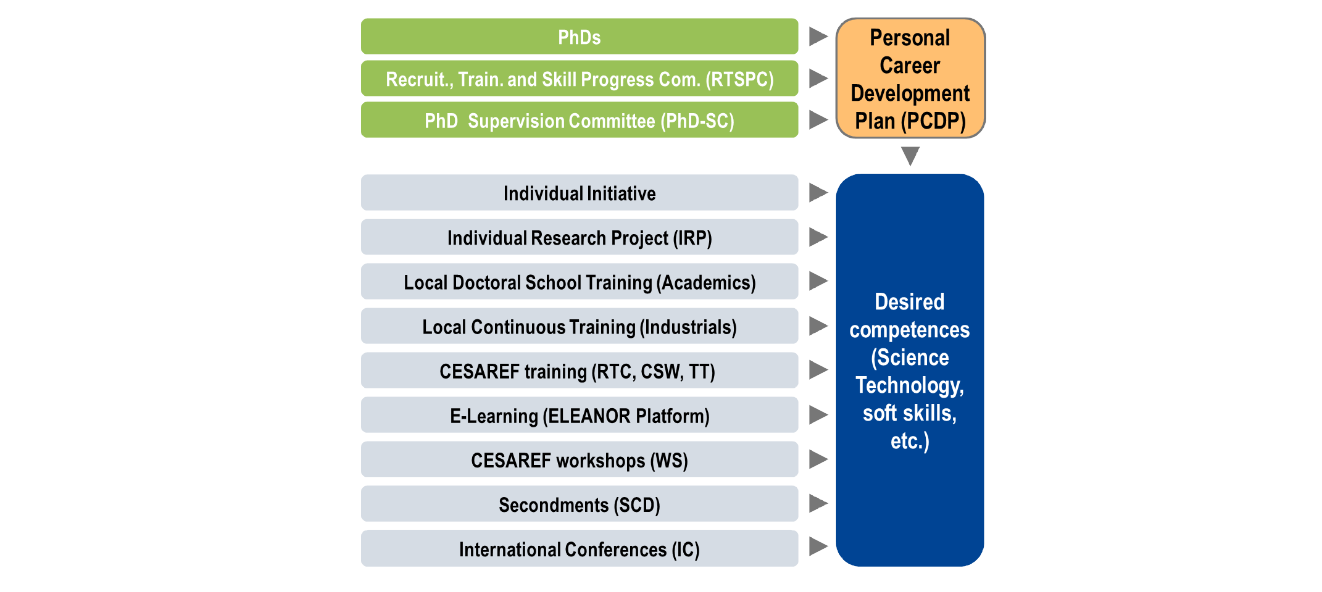

WP 5 - Recruitment, Training and skill progress monitoring

WP 5 will take care about hire, train and prepare PhDs for top level employment. In addition to their individual research projects, each PhD will participate in training events and courses as part of the Network’s activities. It will include formal academic and transferable skills courses, e-learning courses, research training courses on fundamentals, engineering and refractory processing, industrial experiences, bi-lateral and informal roundtable discussions at biannual network meetings, site visits, conferences and poster competitions.

Schematic diagram of the training types covered within CESAREF:

WP 6 - Dissemination and Proactive knowledge transfer to industry

WP 6 will take care about project dissemination activities within CESAREF community, within FIRE network, as well as to the overall scientific community and to the general public (especially students and secondary schools). Ensure that dissemination is compatible with IPRs, confidentiality obligations and interests of owner(s). Promote the presentation of key results during workshops, conferences, and through publication in international journals. Stimulate the organisation of sessions on selected conferences where results from CESAREF are displayed to large audiences.

- Manage the CESAREF website and publish a newsletter every semester;

- Promote science to develop scientific curiosity and questioning among the general public and among the secondary schools;

- Promote engineering to develop interest in careers particularly in the CESAREF fields among students.

WP 7 - Management activities

WP 7 will ensure that the project reaches its objectives in terms of research and training programs according to the contractual time and budget. Apply fair rules within the network to guarantee successfully meet all the assigned objectives and successfully train the 15 PhDs.